The Rise of Geopolymer Bricks and the Decline of Cement Dominance

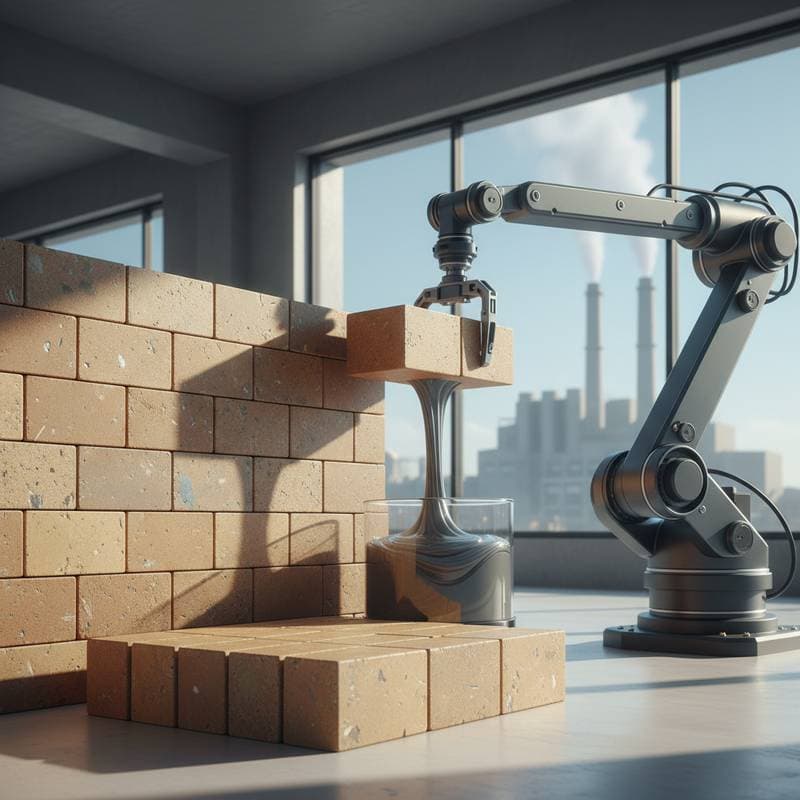

Geopolymer bricks represent a transformative shift in modern construction materials. These innovative blocks provide exceptional strength, sustainability, and enduring performance while avoiding the substantial environmental drawbacks associated with traditional cement products. Rather than relying on energy-intensive processes like limestone calcination, geopolymer bricks form through a sophisticated chemical reaction involving aluminosilicate precursors and alkaline solutions, yielding a rigid, stone-like composition that matches or exceeds the resilience of conventional concrete.

For decades, cement has served as the cornerstone of building projects worldwide due to its reliability and widespread use. However, the production of each ton of cement generates approximately one ton of carbon dioxide, contributing significantly to global emissions. Geopolymer alternatives address this issue by activating waste materials such as fly ash from power plants or ground blast furnace slag, which cure at ambient temperatures and drastically cut energy consumption. This evolution reflects broader industry trends toward materials that balance superior engineering properties with ecological responsibility.

Chemical Foundations: How Geopolymer Bricks Outperform Cement Blocks

At their essence, the distinction between geopolymer bricks and cement blocks stems from fundamental chemical processes. Cement achieves solidity via hydration, where water reacts with clinker to produce calcium silicate hydrates that bind aggregates. Geopolymers, however, polymerize under alkaline conditions, forming a three-dimensional network of silica and alumina tetrahedra that creates an exceptionally dense and impermeable matrix.

This polymerization process enhances resistance to extreme conditions, including temperatures up to 1200 degrees Celsius, aggressive chemicals, and prolonged exposure to moisture or salts. Visually, geopolymer bricks resemble familiar clay or concrete units, yet their microstructure offers greater uniformity and fewer micro-cracks. By integrating recycled aluminosilicates like metakaolin or rice husk ash, these bricks not only minimize landfill waste but also achieve up to 80 percent lower embodied carbon compared to Portland cement equivalents.

Core Advantages of Geopolymer Bricks

-

Enhanced Durability: These bricks withstand thermal cycling without fracturing, ideal for regions with significant temperature fluctuations, and resist sulfate attacks common in coastal or industrial settings.

-

Environmental Sustainability: Production utilizes by-products from coal combustion or steel manufacturing, reducing raw material extraction and emitting 70 to 90 percent less CO2 than cement kilns.

-

Superior Strength: Compressive strengths routinely reach 40 to 60 megapascals, surpassing standard cement blocks and supporting load-bearing applications in multi-story structures.

-

Thermal Resilience: In fire-prone areas, geopolymer bricks maintain structural integrity without spalling, providing safer building envelopes.

-

Minimal Upkeep: The non-porous surface deters water ingress, preventing issues like efflorescence or biological growth, which extends service life beyond 100 years in many cases.

These attributes position geopolymer bricks as a versatile choice for residential dwellings, office complexes, bridges, and urban infrastructure projects.

The Broader Implications of This Material Transition

Cement's longstanding market leadership has relied on established supply networks and builder expertise. Increasingly stringent environmental policies, such as carbon pricing and net-zero building codes, combined with finite limestone reserves, compel the sector to adopt alternatives. Geopolymer bricks align seamlessly with these pressures, offering production scalability that drives costs down to levels competitive with cement, often 10 to 20 percent lower at volume.

From a practical standpoint, this change equips architects and contractors with options that adapt to varied climates and uses. In tropical zones with high humidity, the bricks' low permeability curbs mold proliferation and preserves indoor air quality. In desert environments, they regulate internal temperatures by limiting heat transfer, reducing reliance on mechanical cooling systems. Over the building lifecycle, these benefits culminate in 30 to 50 percent savings on maintenance and energy expenses.

Steps for Integrating Geopolymer Bricks into Projects

Adopting geopolymer bricks demands attention to several implementation factors to maximize their potential.

-

Binder Formulation: Maintain exact proportions, typically a 1:8 to 1:10 ratio of alkaline activator to aluminosilicate source, as specified by suppliers to optimize setting time and final properties.

-

Curing Protocols: Most formulations set at room temperature, but elevated humidity above 70 percent for the first 24 hours ensures uniform hydration and peak strength development.

-

Adhesive and Finish Compatibility: Select geopolymer-specific mortars with silica fume additives for strong bonds, and apply breathable coatings to avoid delamination over time.

-

Sourcing Strategies: Collaborate with certified distributors who provide technical support; regional hubs in Asia and Europe now ship globally, with lead times shrinking to two weeks.

- Assess project specifications to confirm geopolymer suitability.

- Conduct small-scale trials on site to verify performance.

- Train masonry teams on handling differences, such as slightly higher initial weight.

Implementation Tip: Allocate 12 to 15 percent additional material to account for on-site adjustments, ensuring seamless integration without delays.

Advancing Construction Through Geopolymer Innovation

With rising global emphasis on circular economies, geopolymer bricks prepare the industry to meet ambitious sustainability benchmarks. Their inherent compatibility with modular construction techniques accelerates project timelines, while modular designs facilitate disassembly and material reuse at end-of-life. Engineers now incorporate them into seismic-resistant frameworks, leveraging the bricks' ductility to absorb shocks without catastrophic failure.

This material's adoption extends beyond new developments to retrofitting existing structures, where it reinforces facades against climate stressors. Builders report faster installation rates due to the bricks' precision-molded dimensions, cutting labor by up to 20 percent. Ultimately, geopolymer bricks enable a construction paradigm that prioritizes resilience, resource efficiency, and reduced ecological footprints, fostering buildings that endure and inspire for generations.