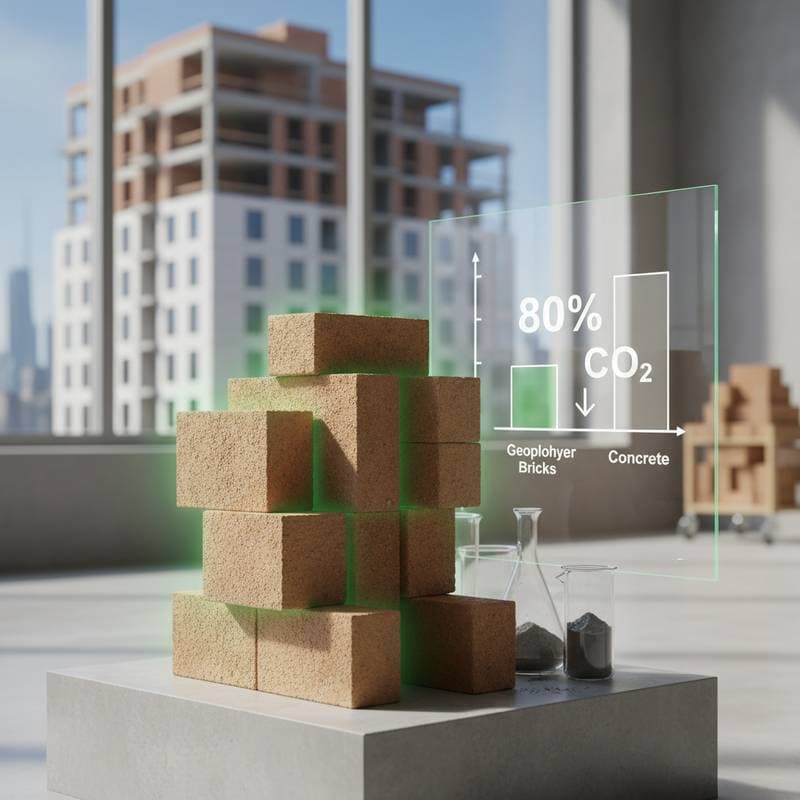

Zero-Cement Bricks Cut Carbon 60% by 2026

Zero-cement geopolymer bricks redefine sustainable masonry, offering 6,000-9,000 PSI strength, 24-48 hour curing, and 60-80% carbon savings. Crafted from fly ash and slag, they provide durable, affordable options that comply with standards and drive eco-conscious building trends into 2026.