Zero-Cement Bricks Match Concrete Strength Without Emissions

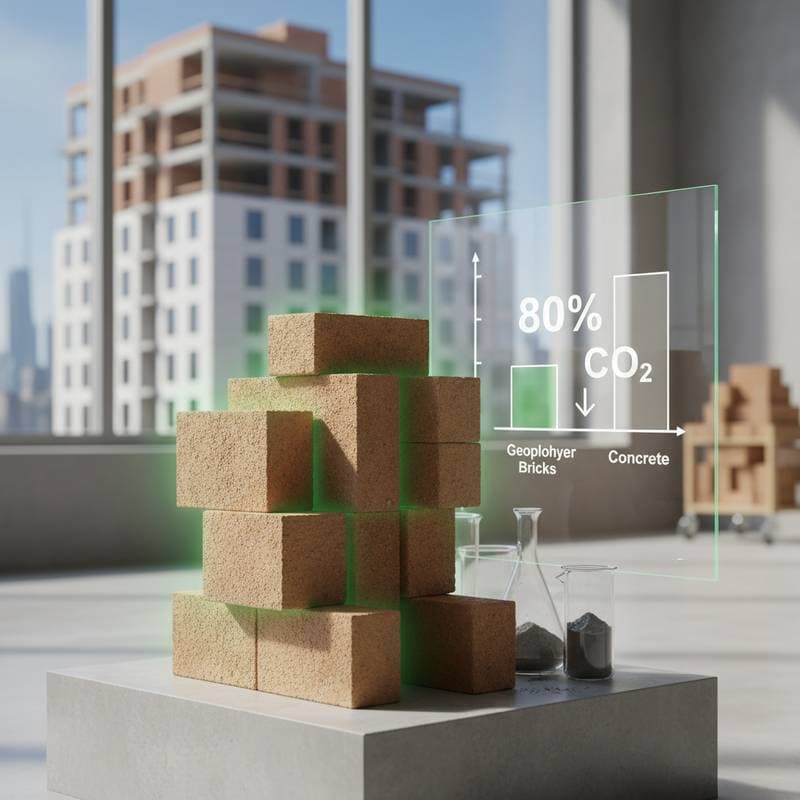

Zero-cement bricks transform masonry by substituting high-emission cement with geopolymer binders derived from industrial byproducts. These units provide superior strength, enhanced durability, and environmental benefits, reducing waste and emissions. As standards evolve and costs align with traditional options, they stand ready to reshape walls, pathways, and residential structures.