Introduction to Geopolymer Bricks

Geopolymer bricks represent an innovative approach to construction materials, leveraging industrial waste to create high-performance alternatives to conventional concrete. These bricks form through a chemical reaction between aluminosilicate materials, such as fly ash, and alkaline activators, resulting in a binder that mimics the properties of cement without the high carbon footprint. This process not only diverts waste from landfills but also yields bricks with compressive strengths exceeding 5,000 psi, often surpassing standard concrete blocks.

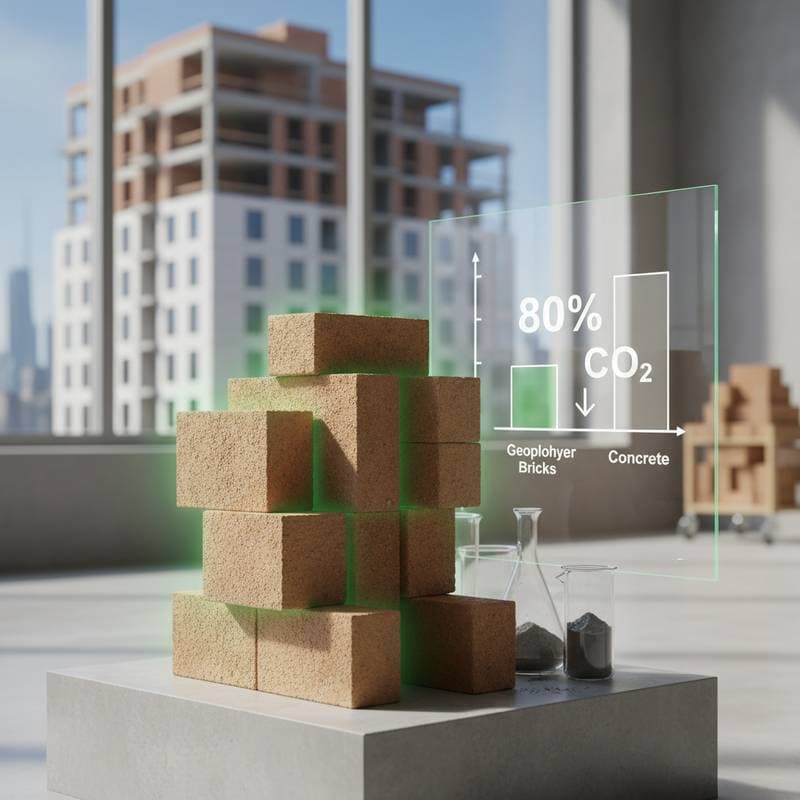

The environmental benefits stand out prominently. Production of geopolymer bricks generates up to 80 percent fewer greenhouse gas emissions than Portland cement-based concrete, primarily because it avoids the energy-intensive clinkering process. Additionally, these bricks exhibit lower thermal conductivity, improving energy efficiency in buildings and contributing to overall sustainability goals.

Key Formulation Considerations

Selecting the right materials ensures optimal performance in geopolymer bricks. Class F fly ash, derived from bituminous coal combustion, provides superior durability and reduced shrinkage compared to Class C varieties. This type of fly ash reacts more effectively with activators, leading to a denser matrix that enhances resistance to environmental stresses.

Activator concentration plays a critical role in the mixture. Solutions with higher molarity, such as 8 to 12 M sodium hydroxide, boost compressive strength but elevate material costs. Balance this by testing small batches to determine the minimum effective concentration for the desired strength.

Aggregate selection affects the final product's workability and load-bearing capacity. Opt for clean, well-graded sand and crushed stone to achieve dense packing and minimize voids. Avoid contaminated aggregates, as impurities can weaken the geopolymer matrix.

Incorporate additives strategically to tailor brick properties. Fibers, such as polypropylene or basalt, reinforce the structure against tensile stresses, while pigments allow for aesthetic customization without compromising integrity.

Cost Planning

Initial material expenses for geopolymer bricks range 10 to 15 percent above those for concrete, driven by activator costs. However, these upfront investments yield substantial long-term savings through reduced maintenance requirements, accelerated curing that shortens project timelines, and superior insulation that lowers operational energy costs. Labor efficiencies further offset expenses, as bricks reach handling strength within days rather than weeks.

Step-by-Step Process for Making and Installing Geopolymer Bricks

1. Prepare the Activator Solution

Dissolve sodium hydroxide pellets in water to achieve the target molarity, then incorporate sodium silicate. This combination forms the alkaline environment necessary for geopolymerization. Allow the solution to cool to room temperature, as exothermic reactions during mixing can otherwise complicate handling.

2. Blend Dry Ingredients

Thoroughly mix fly ash with aggregates and any selected admixtures in a mechanical mixer until the blend appears uniform. Introduce the activator solution gradually while continuing to mix, aiming for a cohesive, workable paste free of lumps. Overmixing can introduce air, so monitor consistency closely.

3. Mold and Compact the Mixture

Pour the geopolymer paste into lubricated molds, distributing it evenly to avoid segregation. Apply vibration for 30 to 60 seconds or tamp manually to expel air pockets, promoting uniform density. Proper compaction directly correlates with higher mechanical strength and surface quality.

4. Cure the Bricks

Cover the filled molds with plastic sheeting to retain moisture, or transfer to a curing chamber maintained at 120°F to 140°F for 24 to 48 hours. This elevated temperature accelerates the geopolymer reaction, achieving early strength. For ambient curing at room temperature, extend the period to five days to ensure full development of properties.

5. Install the Bricks

Use geopolymer-based mortar or low-cement adhesives to lay the cured bricks, ensuring joints measure no more than 3/8 inch thick. Verify alignment with levels and strings at each course, allowing at least 12 hours for joint setting before imposing structural loads. This methodical approach prevents settlement issues.

Troubleshooting Common Issues

Address production challenges promptly to maintain quality.

- For soft or chalky bricks, decrease water in the activator or raise its concentration to strengthen the reaction.

- To prevent excessive cracking, reduce curing temperature or adjust the fly ash to aggregate ratio for better flexibility.

- Achieve even color by mixing thoroughly and distributing the activator uniformly throughout the batch.

- If strength falls short, verify all material proportions and extend curing time as needed.

Maintenance and Long-Term Durability

Geopolymer bricks demand little ongoing care due to their inherent resilience. The compact microstructure effectively withstands salt ingress, repeated freeze-thaw cycles, and surface efflorescence, outperforming traditional concrete in harsh conditions. Schedule inspections every three to five years to assess joint condition, surface erosion, and any biological accumulation.

Repair minor cracks wider than 1/16 inch by applying a compatible polymer mortar, which bonds seamlessly with the original material. With appropriate installation, these bricks endure for over a century, exhibiting minimal structural decline and supporting applications in diverse climates from coastal regions to arid zones.

DIY Feasibility and Professional Guidance

Builders with construction experience can fabricate small quantities of geopolymer bricks using accessible tools like a drum mixer, reusable molds, and a basic heat source for curing. This approach delivers 30 to 40 percent cost reductions versus commercial blocks, ideal for garden walls or custom features. Scale up cautiously, consulting material safety data sheets for handling alkalis.

For load-bearing or extensive projects, engage certified structural engineers and skilled masons to comply with building codes. Professional oversight ensures safety and performance, particularly in seismic or high-wind areas where precise engineering proves essential.

Advancing Construction with Geopolymer Bricks

Integrating geopolymer bricks elevates project outcomes by merging technical excellence with ecological responsibility. Their rapid strength gain streamlines workflows, while emission reductions align with global standards for green building. Select these materials to construct enduring infrastructure that minimizes environmental impact and maximizes value over time.