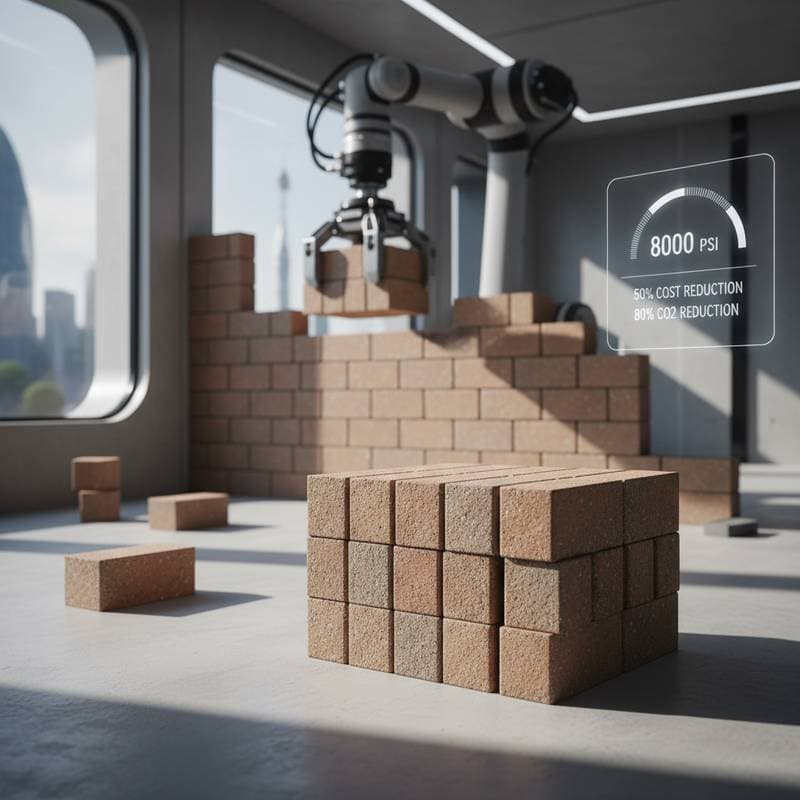

Why Geopolymer Bricks Outperform Traditional Masonry

Geopolymer bricks, made from zero-cement formulations using fly ash and slag, outperform traditional masonry by slashing emissions, boosting durability, and simplifying sustainable builds. Discover their advantages, project planning essentials, and step-by-step guidance to integrate this innovation into your next construction by 2026.