Zero-Cement Bricks: Revolutionizing Masonry by 2026

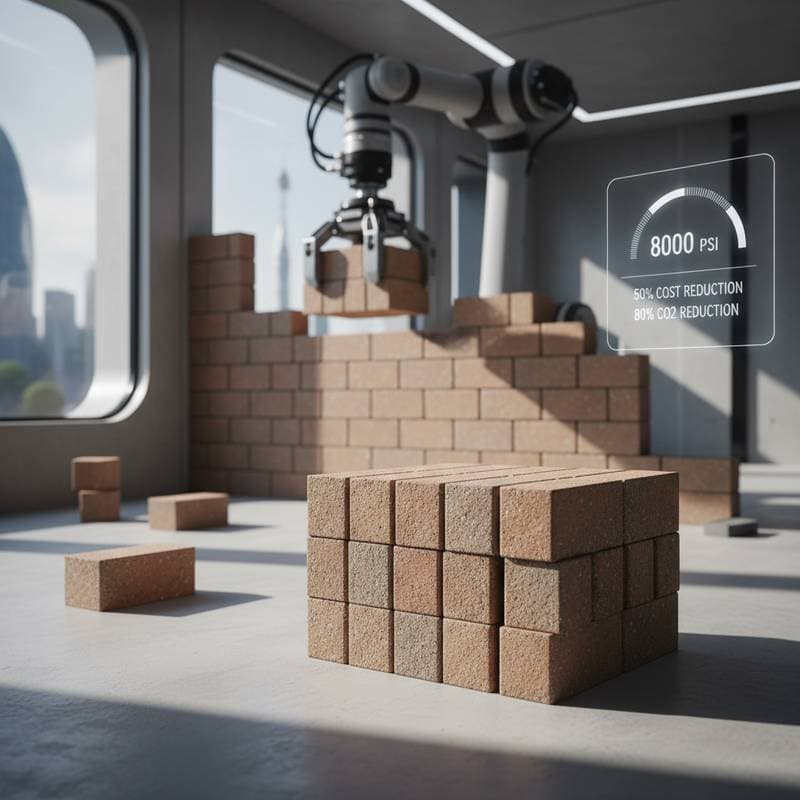

The construction sector faces increasing demands for materials that balance sustainability with high performance. Zero-cement bricks, or geopolymer bricks, emerge as a key innovation in this shift. These units eliminate traditional cement, providing builders and homeowners with options that enhance durability, lower expenses, and support environmental goals. This article covers the essentials of zero-cement bricks, their operational principles, implementation strategies, and reasons they may dominate sustainable building practices by 2026.

Understanding Zero-Cement Bricks

Composition and Key Differences

Zero-cement bricks consist of masonry units produced without Portland cement. Geopolymer binders form the core, derived from industrial byproducts including fly ash, ground granulated blast-furnace slag, or metakaolin. An alkaline activator, such as sodium hydroxide combined with sodium silicate, initiates the reaction that creates a solid matrix. This process mimics the hardening of traditional concrete yet avoids the energy-intensive and emission-heavy cement production.

Environmental and Performance Benefits

These bricks significantly reduce the carbon footprint of construction. By removing cement, emissions drop by as much as 80 percent relative to standard bricks. Production requires no high-temperature firing, unlike clay bricks, which conserves energy. The resulting geopolymer structure features a dense matrix that withstands chemical corrosion, salt exposure, and repeated freeze-thaw cycles. Additionally, these bricks exhibit excellent thermal stability, retaining structural integrity during elevated temperatures and supporting fire-resistant applications.

Preparing Materials and Site

Essential Materials

Gather fly ash or ground granulated blast-furnace slag as the primary binder to substitute for cement. Prepare an alkaline activator solution using sodium hydroxide flakes dissolved in water, then blended with sodium silicate. Incorporate fine aggregates like clean river sand or crushed stone dust to achieve the desired volume and workability. Use distilled water or filtered tap water to maintain reaction precision. For customization, add pigments such as iron oxide to introduce color variations. Select durable molds made from steel or high-density polyethylene, calibrated to standard brick sizes like 8 by 4 by 2.25 inches. Equip the workspace with safety gear, including nitrile gloves, safety goggles, and N95 respirator masks to shield against alkaline irritants.

Site Preparation Steps

Choose a flat, sheltered area for mixing and curing operations to prevent contamination. Target ambient temperatures between 60 degrees Fahrenheit and 90 degrees Fahrenheit to facilitate even geopolymerization. Install a mechanical mixer powered by electricity for consistent blending, and secure a reliable water source for tool rinsing and hydration control. Cover the site with tarps to manage dust and moisture levels effectively.

Production Process

Mixing and Molding

Begin by dry-mixing the fly ash or slag with fine aggregates in a 1:2 ratio by weight. Dissolve sodium hydroxide in water to create a 10-14 molar solution, allowing it to cool before combining with sodium silicate at a 1:2.5 ratio. Gradually add the activator to the dry mix while stirring continuously for five to ten minutes until a uniform, pourable consistency emerges. Pour the mixture into prepared molds, tapping gently to remove air pockets. Demold after 24 hours of initial setting, then transfer bricks to a curing rack.

Curing Protocol

Allow bricks to cure in a humid environment for seven to 28 days, maintaining 75-85 percent relative humidity. Mist surfaces lightly every two days to prevent cracking. Test a subset of bricks at day seven for early strength indicators, aiming for initial hardening that supports handling without deformation.

Quality Assurance and Testing

Strength Assessment

Perform compressive strength tests on cured sample bricks with a calibrated hydraulic press. Target results of at least 8,000 pounds per square inch to meet demands for load-bearing applications. Record data from multiple samples to calculate average values and identify batch variations.

Dimensional and Visual Inspections

Use digital calipers to verify dimensions, ensuring deviations stay within plus or minus 1.5 millimeters for length, width, and height. This precision promotes even mortar joints and uniform wall aesthetics. Examine surfaces for defects like hairline cracks, bubbles, or white efflorescence deposits. Address minor issues by sanding smooth or applying a geopolymer-based patch compound.

Installation Guidelines

Laying and Bonding

Prepare the foundation by leveling and dampening the base surface. Mix geopolymer mortar using the same binder-activator ratio as the bricks, applying a 3/8-inch bed joint. Lay bricks in a running bond pattern, staggering joints by half a brick for stability. Tool joints concave after initial set to enhance weather resistance.

Integration with Structures

Secure bricks to existing frameworks using compatible anchors if retrofitting. For load-bearing walls, consult structural engineers to confirm compliance with local building codes. Allow full curing before applying finishes like plaster or paint, typically after 28 days.

Maintenance and Long-Term Care

Zero-cement bricks demand little ongoing attention, yet regular evaluations preserve their performance.

Scheduled Inspections

Examine walls biannually for cracks exceeding 1/16 inch in width, addressing them promptly with epoxy fillers. Refresh mortar joints through repointing every 10 to 12 years to maintain weatherproofing. Wash exteriors annually using a mild alkaline detergent and a low-pressure hose set below 500 PSI.

Enhancing Durability

In regions with high salinity or moisture, apply a silane-based, breathable sealant every five years to deter staining and efflorescence. Avoid abrasive cleaners that could erode the surface matrix. These measures extend service life in challenging environments.

Expected Longevity

Properly installed and maintained geopolymer brick structures endure 75 to 100 years, often outlasting conventional masonry due to inherent chemical stability.

Pro Tips for Implementation

Maintain strict moisture control during mixing, adhering to a water-to-binder ratio of 0.3 to 0.4 to preserve bond integrity. Source byproducts from local industrial sites to minimize transport emissions and expenses. Reserve at least 150 square feet of covered space per 1,000 bricks for organized curing and storage. Shield curing areas from direct sunlight in warm regions to avoid thermal gradients that cause fissures. Maintain detailed logs of mix ratios, curing conditions, and test outcomes for traceability and optimization in subsequent batches.

Advancing Sustainable Construction Practices

Zero-cement bricks facilitate a transition to environmentally conscious building without compromising on robustness or endurance. Their use of waste materials, emission reductions, and streamlined production position them as a superior alternative to traditional options. Builders undertaking residential or commercial projects gain practical tools through mastery of geopolymer techniques. Embracing these bricks now prepares structures for long-term resilience and aligns with evolving standards in green architecture.