Introduction to 3D Printed Concrete in Home Building

3D printed concrete represents a significant advancement in construction technology. This process uses large-scale printers to extrude concrete layer by layer, following precise digital designs. Unlike traditional methods that rely on manual labor and extensive formwork, 3D printing automates wall construction, which leads to notable savings in time and resources.

The technology addresses key challenges in housing, such as rising costs and labor shortages. Projects that once took months can now complete in days for the structural phase. Moreover, the approach supports sustainable practices by optimizing material use and reducing on-site waste. Homeowners and developers benefit from customizable designs that maintain structural integrity while lowering overall expenses.

Key Benefits for Affordable Housing

One primary advantage lies in cost reduction. Traditional concrete pouring requires extensive scaffolding and labor, but 3D printing eliminates much of this overhead. Estimates suggest savings of up to 30 percent on material and labor costs for standard homes. The precision of the printing process also minimizes errors, further cutting expenses related to rework.

Build times shorten dramatically as well. A single printer can construct exterior walls in 24 to 48 hours, depending on the design complexity. This acceleration allows projects to progress faster to finishing stages, enabling quicker occupancy. Sustainability improves through the use of locally sourced or recycled aggregates, which lowers the carbon footprint associated with transportation.

Durability remains a hallmark of printed concrete structures. The layered composition creates strong bonds between layers, resulting in walls resistant to seismic activity and extreme weather. Customizable features, such as integrated insulation channels, enhance energy efficiency without additional construction steps.

Essential Equipment and Materials

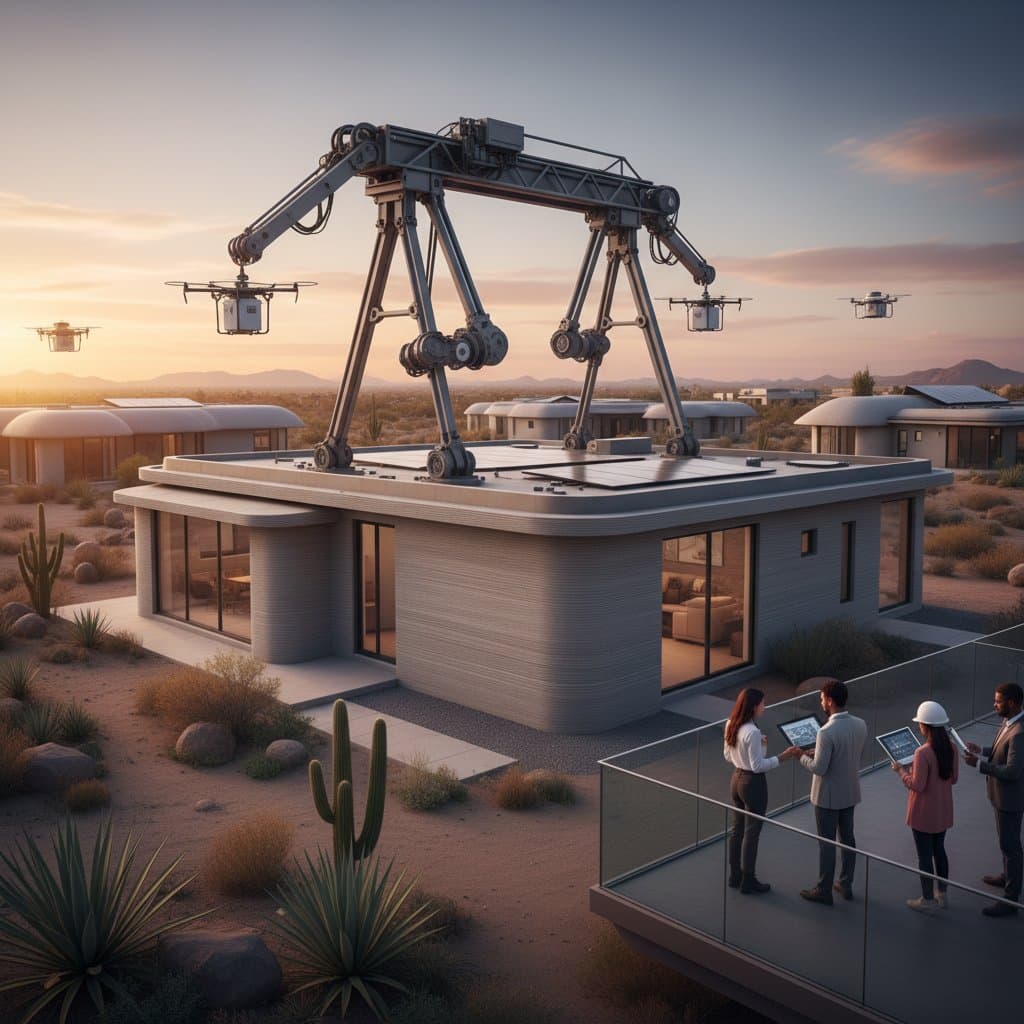

To undertake a 3D printed concrete project, assemble the right tools and supplies. The core equipment includes a gantry-style 3D printer with rails for movement along the building footprint. This machine features an extruder nozzle that deposits concrete at controlled rates. A telehandler or forklift assists in safely transporting material batches to the mixing station.

Power sources, such as generators, ensure uninterrupted operation, especially in remote sites. Safety gear, including helmets, gloves, and protective eyewear, protects workers from dust and machinery hazards. Software for design and printer control translates architectural plans into printable files.

Materials List with Buffer

Select high-quality components to achieve optimal results. The foundation includes:

- Cement or specialized binder mix for strength and adhesion.

- Fine aggregates, such as sand, to provide texture and stability.

- Reinforcement mesh or fibers to enhance tensile strength.

- Curing compound to retain moisture during hardening.

- Sealant and protective coating for weather resistance.

- Additives for flow control, ensuring smooth extrusion.

Include a 10 percent buffer in quantities to account for waste from test prints and calibration. This precaution prevents delays due to shortages during active printing.

Pro Tip: Consider renting the printer for single projects, as purchase costs are substantial and demand specialized maintenance knowledge.

Step-by-Step Guide to 3D Printing Concrete Walls

Follow these instructions meticulously to ensure a successful build. Each phase builds on the previous one, emphasizing precision and safety.

1. Prepare the Foundation

Begin with a reinforced concrete slab or footing that aligns with the structural engineering plans. Level the surface to within millimeters, as the printer depends on this flat base for accuracy. Install anchors and embed conduits for utilities prior to printing to avoid later disruptions.

2. Calibrate the Printer

Position the printer rails securely around the foundation perimeter. Technicians align the system, verify nozzle height above the surface, and adjust extrusion speeds. Conduct a test print of a small section to evaluate mix flow and layer bonding, making refinements as needed.

3. Load and Test the Concrete Mix

Mix the concrete according to the printer manufacturer's guidelines, typically involving a pumpable consistency. Observe the extrusion to confirm proper viscosity; the material should hold shape without collapsing. Fine-tune water content or additives if the mix flows unevenly or slumps.

4. Print the Walls

Initiate printing from designated corners, progressing in continuous layers. Overlap each new layer slightly with the one below for seamless integration. Maintain steady nozzle pressure and movement speed to build uniform walls. Pause briefly at set intervals to check levelness with a spirit tool.

5. Integrate Reinforcement and Conduits

Advanced printers insert reinforcement automatically, but many require manual intervention. Halt printing at predetermined heights to place steel cables, mesh, or fiber sleeves. Align these elements precisely with plans for electrical wiring and plumbing runs.

6. Incorporate Openings and Details

The digital design file directs the printer to skip areas for doors and windows. Measure these openings regularly during the process to catch any deviations early. Minor adjustments prevent compounding errors as the structure rises.

7. Cure the Printed Structure

Apply curing blankets or automated misting immediately after printing to control moisture loss. Shield the walls from direct sun, wind, or rain to avoid rapid drying and cracks. Permit full curing, which may take several days, before imposing loads like roofing.

8. Apply Surface Finishes

Once cured, smooth or texture the walls to match aesthetic preferences. Coat exteriors with sealants to repel water and stains. For interiors, apply plaster or specialized paints compatible with concrete substrates.

Quality Checkpoint: Verify wall plumbness, dimensional accuracy against plans, and absence of voids or delaminations. Repair any issues promptly with matching mortar.

Practical Tips for Success

Maximize efficiency with these strategies:

- Purchase 10 percent extra mix to cover testing and waste.

- Erect a shading canopy in warm regions to regulate curing conditions.

- Adhere to manufacturer specifications for nozzle speeds and layer heights.

- Employ a laser level to monitor alignment periodically and correct drift.

- Engage local structural engineers to validate reinforcement for load-bearing elements.

Enhancing and Completing the Build

After printing the core structure, integrate insulation within wall cavities for thermal performance. Install roofing systems suited to the design, such as lightweight panels that complement the concrete base. Consider sustainable additions like solar arrays or green roofs to boost energy independence.

Exterior enhancements unify the project. Print complementary features, such as boundary walls or garden elements, using the same technology. Incorporate low-voltage lighting in pathways or wall recesses to improve usability and visual appeal after dark.

Long-Term Maintenance Strategies

3D printed concrete demands minimal ongoing care due to its robust nature. Conduct annual inspections for surface cracks or sealant degradation. Clean walls with a gentle detergent solution and low-pressure rinse to remove dirt buildup. Refresh protective sealants every three to five years to maintain barrier properties.

For specialized mixes, such as those with fibers or geopolymers, refer to supplier guidelines for tailored curing and inspection routines. Prompt attention to minor issues preserves the structure's longevity and appearance.

Realizing Efficient, Innovative Homes

3D printed concrete empowers builders to deliver housing that is both economical and forward-thinking. This method not only trims budgets and timelines but also opens doors to creative, eco-friendly designs. As adoption grows, it promises broader access to quality homes, reshaping communities one layer at a time.