- Key decision factors: Select smart pavers based on expected traffic volume, specific data objectives, available budget, and compatibility with current infrastructure.

Planning a Smart Paver Installation

Before incorporating smart pavers into a commercial property, establish a precise plan for data collection and application. This approach guarantees tangible benefits while minimizing excess expenses and technical hurdles.

Define Objectives and Data Priorities

Determine primary aims, such as:

- Monitoring pedestrian volume to refine retail strategies.

- Assessing directional movement to streamline site layouts.

- Tracking surface temperature and moisture levels for proactive maintenance.

- Capturing event frequencies or dwell durations to identify high-engagement areas.

These choices influence sensor selections, network configurations, and data storage solutions.

Permits and Compliance

Smart paver projects typically align with routine paving regulations, yet adherence to local codes for electrical installations, excavation, and accessibility remains essential. For municipal initiatives, collaborate with public works or transportation authorities to meet safety protocols and data privacy requirements.

Cost Breakdown and Budgeting

For a typical mid-sized commercial pathway, costs allocate as follows:

- Materials (45%): Including pavers, sensors, protective conduits, sealants, and foundational aggregates.

- Labor (35%): Covering site excavation, surface leveling, paver placement, electrical wiring, and system calibration.

- Technology Integration (20%): Encompassing network configuration, software subscriptions, and data analytics platforms.

Although upfront investments exceed those of conventional paving, savings emerge over time from optimized maintenance, superior space utilization, and targeted marketing insights.

Step-by-Step Installation Process

1. Excavation and Base Preparation

Clear away existing surfaces to the specified depth, determined by anticipated loads. Compact the subgrade with a plate compactor to achieve 95 percent of maximum density for stability.

2. Install Conduits and Power Supply Lines

Position flexible conduits in trenches positioned at least 4 inches beneath the base layer. Direct lines to perimeter junction boxes or central control units, and fasten all joints with durable, weather-resistant components.

3. Place and Level Bedding Layer

Distribute bedding sand uniformly and smooth it with a screed tool. Achieve a uniform depth of approximately 1 inch to promote balanced weight distribution across the surface.

4. Set Pavers with Integrated Sensors

Align each smart paver precisely, orienting sensors according to the predefined schematic. Preserve joint gaps between 1/8 and 1/4 inch, and tap pavers into place using a rubber mallet to avoid compromising internal electronics.

5. Connect Communication Modules

Link connectors or initiate wireless synchronization upon completing each sensor row. Confirm data transmission from all components prior to advancing.

6. Apply Joint Sand and Compact Surface

Brush polymeric sand into the joints, then apply gentle compaction with a plate compactor equipped with a padded surface. This method locks pavers in position without disturbing sensor alignments.

7. Calibrate and Validate Data Output

After full assembly, perform walking tests along designated routes to assess sensor performance and precision. Fine-tune parameters via the control interface to match anticipated metrics accurately.

Troubleshooting Common Issues

Well-executed installations may still encounter obstacles. Early identification of problems averts expensive fixes.

- Data dropouts: Typically arise from signal weaknesses or power failures. Inspect antenna positions or substitute depleted batteries.

- False readings: Often triggered by non-pedestrian loads like machinery. Designate restricted zones or adjust sensitivity levels.

- Moisture interference: Ingress can disrupt sensor functions. Confirm pavers adhere to IP67 waterproof ratings.

- Uneven response zones: Stem from inadequate base compaction. Excavate and re-level problematic sections as needed.

For ongoing difficulties, engage the manufacturer or a certified specialist for thorough diagnostics.

DIY Feasibility and Professional Considerations

Standard paver projects suit DIY efforts, but smart systems demand advanced expertise.

When DIY Is Possible

Individuals with solid construction backgrounds can manage excavation, base setup, and paver positioning for wireless, battery-operated setups. Such self-installation may reduce costs by 20 to 30 percent, although tool rentals and extended timelines could diminish those gains.

When to Hire Professionals

Opt for expert services when the scope involves:

- Wired electrical systems necessitating conduit installations.

- Expansive commercial areas surpassing 500 square feet.

- Linkages to established platforms, such as facility management tools.

- Busy public venues requiring formal safety validations.

Select firms proficient in masonry and low-voltage wiring. Confirm licensing, insurance coverage, and knowledge of regional data-handling laws.

Maximizing Returns from Smart Paver Deployments

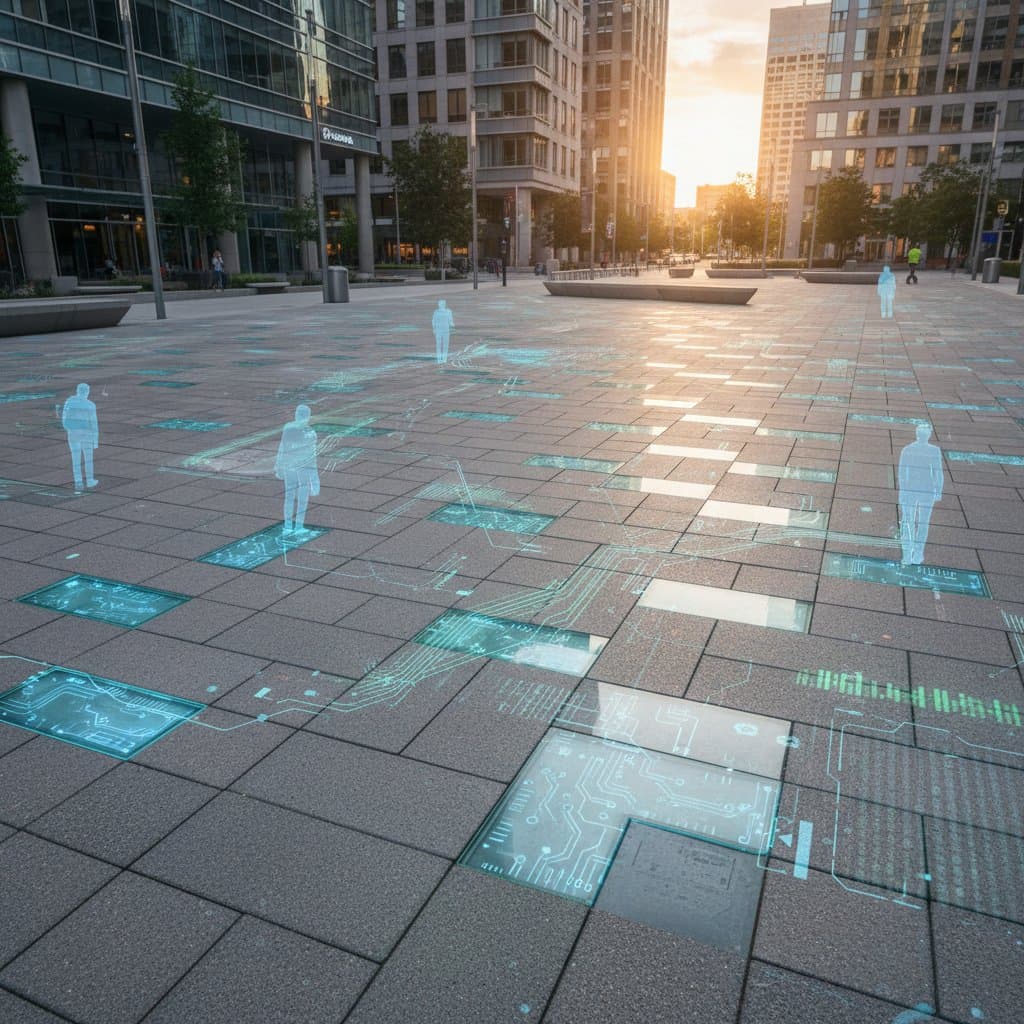

Smart pavers fuse traditional stonework with cutting-edge analytics, transforming inert pathways into dynamic monitoring networks. They inform layout adjustments, elevate user safety, and deepen interactions with visitors.

Through meticulous preparation, accurate execution, and regular adjustments, these installations evolve beyond mere walkways. They serve as analytical assets, illuminating visitor behaviors to support evidence-based enhancements and sustained performance.