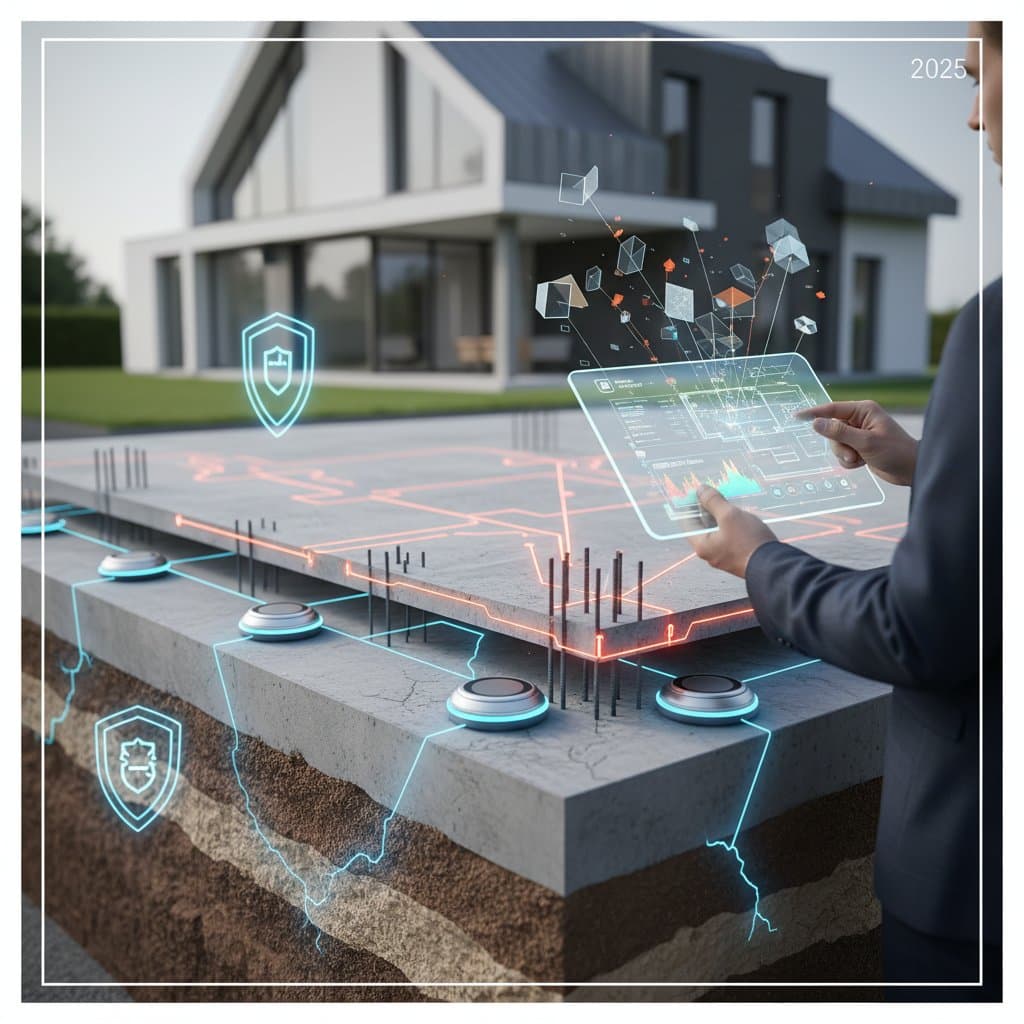

Understanding Smart Sensors for Foundation Health

Smart sensors are transforming the way homeowners and builders monitor foundation stability. These compact devices track subtle shifts, vibrations, and moisture levels well before cracks become visible on walls or floors. By identifying early warning signs, smart sensors help prevent expensive structural repairs and ensure building safety.

Traditional inspections depend on visible damage or manual measurements. In contrast, smart sensors deliver continuous data and issue alerts when conditions deviate from normal. This predictive capability represents a significant advancement in foundation maintenance and construction quality control.

Why Early Detection Matters

The foundation bears the weight of the entire structure. Minor variations in soil moisture, temperature, or load distribution can lead to uneven settling. If these issues go undetected, they result in cracks, sticking doors, and potential structural failure. Detecting movement prior to visible damage enables prompt interventions, such as improving soil drainage or applying targeted underpinning.

Early detection also lowers repair expenses. Addressing soil drainage or re-leveling the foundation before cracks form proves far more cost-effective than comprehensive structural fixes. Smart sensors facilitate this forward-thinking strategy through real-time performance data.

How Smart Sensors Work

Smart foundation sensors employ accelerometers, strain gauges, and moisture probes to collect data on movement, pressure, and environmental factors. These devices transmit information wirelessly via low-power networks or Wi-Fi to a central monitoring platform. Alerts activate when measurements surpass predefined thresholds, notifying homeowners or property managers.

Key data points include:

- Vertical and horizontal displacement to monitor settling or shifting

- Soil moisture content to pinpoint drainage or plumbing problems

- Temperature gradients that affect material expansion and contraction

- Vibration levels indicating nearby construction or seismic events

Predictive algorithms analyze this combined data to forecast potential risks. Such detailed insights support preventive maintenance over reactive measures.

Planning Your Smart Foundation Monitoring System

Careful planning precedes the installation of a monitoring network. Although many systems accommodate skilled do-it-yourself installers, certain scenarios demand input from professional engineers.

Assessing the Site

Examine soil type, slope, and drainage patterns. Clay soils expand and contract significantly with moisture changes, whereas sandy soils drain rapidly yet settle unevenly. Locate existing cracks or uneven floors to identify high-stress areas. Evaluate nearby trees, downspouts, or irrigation systems that alter soil moisture levels.

If the structure exhibits signs of substantial movement, consult a structural engineer prior to installation. Professionals must design any necessary foundation stabilization or underpinning.

Measurements to Take

Measure the foundation perimeter and designate potential sensor positions. Standard setups place one sensor at each corner, with additional units along extended walls. Space sensors 10 to 15 feet apart for sufficient coverage in typical homes. Use a laser level to document elevation variations across the slab or basement floor, establishing a baseline map.

Environmental Factors to Consider

Account for these elements to interpret sensor data effectively:

- Soil drainage and seasonal moisture fluctuations

- Groundwater levels

- Local seismic risks

- Freeze-thaw cycles

- Proximity to heavy traffic or construction areas

Choosing Sensor Types

Tilt and Motion Sensors

These measure angular displacement or tilt in foundation walls.

Pros: Straightforward installation and dependable for settlement detection.

Cons: Limited effectiveness in spotting moisture-induced movement.

Cost: Moderate.

Skill Level: Intermediate.

Strain Gauges

These detect minute elongations in structural materials.

Pros: Highly sensitive, particularly suited for concrete foundations.

Cons: Demand precise calibration and secure adhesive attachment.

Cost: Premium.

Skill Level: Advanced; professional installation advised.

Moisture and Temperature Probes

These monitor environmental conditions impacting soil movement.

Pros: Valuable for preventive upkeep and risk forecasting.

Cons: Provide indirect assessments of structural stress.

Cost: Affordable.

Skill Level: Beginner-friendly with setup guidance.

Integrated systems often blend these sensor types for thorough oversight.

Gathering Tools and Materials

Hand Tools

- Tape measure for precise spacing

- Level and chalk line for marking positions

- Screwdriver set for securing brackets

Power Tools

- Drill equipped with masonry bits for concrete work

- Cordless screwdriver for panel assembly

Rental Equipment

- Laser level for accurate elevation mapping

- Data receiver or hub, if not part of the kit

Materials List

- Smart sensors including mounting hardware

- Wireless hub or gateway

- Waterproof sealant for exterior sensors

- Extension cables or conduits as required

Purchase 10 percent additional mounting hardware to account for errors like misplaced anchors or broken brackets.

Step-by-Step Installation and Setup

- Map the layout. Position markers around the foundation perimeter with even spacing to enable consistent data analysis.

- Prepare surfaces. Remove dust and debris from concrete or masonry; ensure dryness for optimal adhesion or fastening.

- Install sensors. Attach each unit following the manufacturer orientation instructions, maintaining level alignment with foundation edges.

- Connect to the network. Activate sensors and pair them with the central hub; verify data transmission prior to enclosing units.

- Seal and protect. Apply waterproof sealant to outdoor sensors and route cables through conduit to shield from moisture and pests.

- Record baseline readings. Log initial values for displacement, moisture, and temperature to set comparison standards.

- Set alert thresholds. Configure limits for movement and moisture according to site specifics, adhering to manufacturer guidelines.

- Monitor regularly. Examine dashboard overviews weekly, focusing on gradual patterns rather than isolated anomalies.

Verify that sensors deliver steady data within anticipated ranges. Inconsistent or absent signals suggest loose mounts or connectivity problems.

When to Involve a Professional

Engage a structural engineer if sensors indicate swift displacement, ongoing moisture shifts, or notable tilt. While do-it-yourself monitoring aids early spotting, experts must assess serious irregularities. Avoid attempting foundation lifting or underpinning without professional blueprints.

Maintaining Your Monitoring System

Smart sensors require periodic upkeep. Swap out batteries or recharge modules per schedule. Gently clean units to avoid dust accumulation. Annually cross-verify data with manual leveling to confirm precision.

Enhancing Your System for Greater Protection

Integrate smart sensors with home automation platforms for automated responses, such as activating sump pumps during high moisture alerts. Incorporate AI-driven analytics to refine predictions based on historical data and weather forecasts. Pair with security cameras to visually confirm sensor-detected vibrations from external sources. These upgrades extend monitoring beyond basics, fostering a resilient home environment.

Avoiding Pitfalls in Foundation Monitoring

Uneven sensor mounting leads to inaccurate readings; remedy by reinstalling with a level and checking alignment. Neglecting baseline data hinders trend analysis; always capture initial metrics before activation. Failing to resolve root causes, like clogged gutters or improper grading, renders alerts ineffective; investigate and correct underlying drainage issues promptly. Regular calibration prevents drift in measurements; schedule professional tune-ups every two years for long-term reliability.